Retsch sieve shakers and sieving machines cover a wide measuring range. Furthermore, thanks to different sieving motions and sieve sizes, the sieve shaker range is suitable for almost any bulk material.

Retsch sieve shakers and sieving machines produce exact and reproducible results and comply with the requirements for the test materials monitoring in accordance with DIN EN ISO 9000.

Sieve Shakers and Sievers

SKU: 11593

Available in countries :

Models

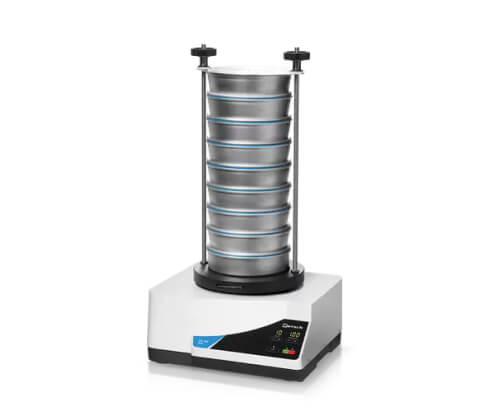

Vibratory Sieve Shakers AS 200 Basic, AS 200 Digit cA and AS 200 Control

Retsch’s vibratory sieve shakers of the series AS 200 are used in research & development, quality control of raw materials, interim and finished products and in production monitoring. The controllable electromagnetic drive offers optimal adaption to every product. Even after short sieving times sharp fractions are obtained.

The AS 200 basic sieve shaker is the economical option of the series with familiar Retsch quality and reliability. It features a digital setting and displays the performance and time. The AS 200 digit cA sieve shaker on the other hand is recommended whenever controlled amplitude, digital display of vibration height as well as time and interval operation are required.

With its all-digital controls, up to 99 sieving programs and calibration certificate the sieve shaker AS 200 control is indispensable for all users who put their focus on precision and operational convenience as well as the need to comply with the guidelines of the ISO 9001. The AS 200 control ensures 100% reproducibility of sieving results once calibrated, not only in one device, but among all AS 200 control units! Accordingly, this model is ideally suited to verify particle size distributions for quality control, e.g. between suppliers and customers.

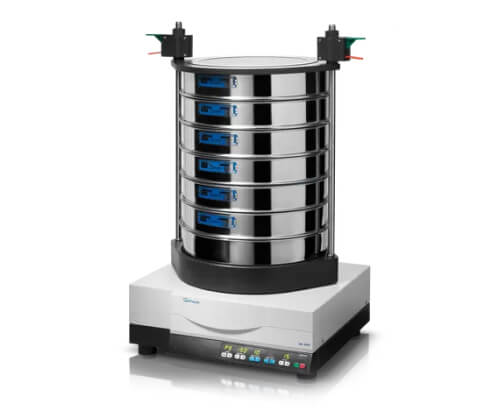

Vibratory Sieve Shakers AS 300 Control, AS 400 Control, AS 450 Control and AS 450 Basic

Same as the AS 200 series, these Retsch analytical sieve shakers are used in research & development, quality control of raw materials, interim and finished products and production monitoring. The controllable electromagnetic drive offers an ideal adaption for every product. Even after short sieving times sharp fractions are obtained.

The AS 300 control is designed with an emphasis for test sieves with a diameter of 305 mm (12″). In comparison with a diameter of 200 mm, the sieving surface is increased by 2.25. Hence, the average sieving times can be greatly reduced with the AS 300 control. The AS 400 control is used in the case of sieving dry goods with test sieves of a diameter up to 400 mm. Here, the uniform, horizontal circular motion guarantees exact separation of fine and coarse-grained products.

With their all-digital controls and calibration certificate the sieve shakers AS 300 and 400 control are a must for all users whos emphasis lies with precision and operational convenience as well as need to comply with the guidelines of the ISO 9001. The sieve shaker AS 450 control is the first siever for 400 mm and 450 mm sieves by Retsch which operates with a three-dimensional sieving motion. Both dry and wet sieving are possible. An amplitude up to 2.2 mm even with maximum loads up to 25 kg are possible through the optimized electromagnetic drive with Retsch’s CET Technology. Therefore, the AS 450 is superior to all other known sieve shakers based on conventional electromagnetic or imbalance drives.

The AS 450 basic is the alternative to the AS 450 control sieve shaker for a lower budget. This sieve shaker handles a size range from 25 μm to 125 mm and accepts loads of up to 15 kg. Time and amplitude can be set digitally. Furthermore, a memory function allows storage of one program. The AS 450 basic can be used for both dry and wet sieving. It is the economic solution for customers who require to sieve larger quantities of dry material with reliable results.

Air Jet Sieve AS 200 JET

The new Air Jet Sieve AS 200 JET is suited for sieve cuts of powdered materials which need efficient dispersion and deagglomeration. With the option to store up to 10 SOPs and the automatic vacuum regulator (accessory) reproducible and meaningful results are guaranteed.

Innovative features like for example the Open Mesh function, the selection of the nozzle speed or the optional use of standard 2″” high test sieves perfect the new air jet technology.

Air Jet Sieve AS 200 TAP

The analytical sieve shaker AS 200 TAP is used in research & development, quality control of raw materials, interim and finished products and in production monitoring.

Retsch’s AS 200 TAP tapping motion supports the sieve analysis of certain products like activated carbon, metal powder, abrasives, spices and diamonds, as indicated in the corresponding standards.