Grinding Machines for OES and XRF sample preparation

HERZOG offers the right solution for preparation for all user needs - from full automation to manual stand-alone machines. Various options are available, including machines with a sanding belt or holder / holder for coarse and ...

Read more

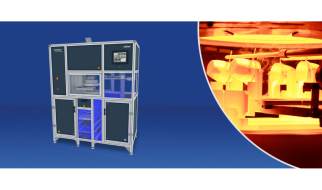

Fusion Machines for XRF Sample Preparation

Fusion in XRF is the principle of merging a sample of powder and lithium borate into a glass bead. The complex preparation process and high safety requirements place high demands on machines for this type of sample preparation....

Read more