Having understood the increasing need for this type of services, the Analysis laboratory for calibration, validation and testing according to ISO 17025 started in 2011, gaining a great number of satisfied customers since then.

Laboratory for Calibration and Validation

In addition to calibration and testing of monitoring and measuring equipment, Analysis Laboratory for Calibration and Validation, thanks primarily to the expertise of the staff, provides additional services such as consulting, training, as well as technical and metrological support.

Through consulting services, the Laboratory for Calibration and Validation offers expertise in the management of measurement processes, providing adequate solutions that guarantee significant savings.

Advantages of our Laboratory

- Management and optimization of measurement processes

- All services meet the requirements of ISO 9001 and ISO 17025

- Unified electronic database of standard measuring equipment, as well as the database of users’ measuring equipment

- Effective monitoring of recalibration services for our users’ measuring equipment

- Engineering, training, support and consulting services

- Assistance in analyzing / defining the development of measurement processes in the laboratories of our users

- Support in the selection, procurement and implementation of measuring equipment

- Training the users of measuring equipment related to the use, maintenance and performance of the measurements

- Organizing interlaboratory comparisons for calibration laboratories

- Support to users of our services regarding processes of internal controls and checks, according to metrological requirements of ISO 17025 standard

- We offer filters for internal control of UV-VIS spectrophotometers, colorimeters, atomic absorption spectrometers, etc., as well as Elisa microplate readers (picture to the right). Contact us for more information.

Key benefits of the Laboratory

- We provide a range of services you may need in one place

- A range of technical skills and services unique in Serbia

- Recognized experience and competence in the processes of measuring and managing instruments and measuring equipment

- Providing fast services to our customers

- Safety and quality policy

Scope of accreditation

Analysis Laboratory for calibration and validation is accredited for calibration and testing according to ISO 17025 by the Accreditation Body of Serbia (Akreditacionog tela Srbije (ATS)) in several areas:

- Mechanical quantities (mass measurements)

- Quantity of fluids (volume measurements)

- Optical quantities (measurements of spectral transmittance/absorbance, turbidity, polarimetry, index of refraction etc.)

- Thermodynamics quantity (measurements for maintaining the set referent conditions – autoclaves, liquid baths, incubators, dry chambers, climatic chambers, etc.)

- Chemical quantities and reference materials (measurements of pH value, conductivity, refractive index, concentration, density, etc.)

- Air testing

Calibration of instruments for mass measurement: electromechanical scales with non-automatic operation / Analytical, technical and industrial scales up to 10 kg.

Calibration is performed using weights of class E2 in accordance with EURAMET / cg-18 / v03.

Calibration range: from 1 mg to 10 kg.

Calibration of instruments for volume measurement: pipettes and burettes with piston, dispensers

Gravimetric method ISO 8655-6: 2002; EURAMET / cg-19 (version 2.1 03/2012)

Calibration range for pipettes: from 10 microliters to 20 ml

Burette calibration range: from 1 ml to 100 ml

Dispenser calibration range: from 1 ml to 100 ml

Calibration of instruments for measuring optical quantities: absorption spectrophotometers with and without flow cell, OIML, R 135: 2004, Nist Special Publication, 2260-166: 1994, direct comparison method with etalon filters, with the calibration range from 0 A to 3 A or 0, 1% T to 100% T. The measuring range of wavelengths: 200 nm to 1000 nm.

Photometers (Elisa readers, biochemical analyzers, colorimeters), atomic absorption spectrophotometers with and without flow cell, OIML, R 135: 2004, Nist Special

Publication, 2260-166: 1994, direct comparison method with etalon filters, laboratory calibration range is 0 up to 3 A or from 0.1% T to 100% T. The measuring range of wavelengths: 200 nm to 1000 nm.

Infrared spectrophotometers with Fourier transform (FTIR, FTNIR), NIST Special Publication, 260-123, ASTM E 1421-99, direct comparison method with etalon filters, calibration range: 0% T to 100% T, or wave number: 400 cm-1 to 4000 cm-1.

Atomic absorption spectrophotometers (AAS), OIML, R 100: 1991, direct comparison method with standard filters, with the calibration range from 0.1% T to 50% T. The measuring range of wavelengths: 200 nm to 900 nm.

Polarimeters, OIML R 14, direct comparison method with quartz filters (polarizers), the measuring range of the polarization angle unit measurements: 0° to 90°.

Turbidimeters, direct comparison method with SRM, EPA Method 180.1

UV / VIS and PDA liquid chromatography detectors, OIML, R 135: 2004, Nist Special Publication, 2260-166: 1994, direct comparison method with standard filters, with the calibration range from 0 to 3 A and 0.1% T to 100% T. The measuring range of wavelength: 200 nm to 1000 nm.

Optically neutral spectrally permeable materials, spectral coefficient transmittance / absorpbance and wavelength standards.

Calibration of instruments for temperature measurement: thermo chambers for various purposes (climatic chambers, incubators, drying ovens, sterilizers, thermostatic baths, heating ovens, autoclaves).

The standard calibration method used for calibration and mapping of thermo chambers is the direct method of measurement using different types of standard probes (Pt probes, thermocouples types K and T), in accordance with DKD-R-5-7.

The temperature range: -20°C to 1000°C, depending on the type of chamber.

Inductively coupled plasma (ICP) atomic spectrometers for measuring metals in water, OIML, R 116, direct comparison method with SRM. The measuring range of concentration units: from 0.1 mg/l to 10 mg/l or 10 mg/l to 100 mg/l

pH-meters, ISO 10523: 1994, EPA 150, direct comparison method with SRM, the measuring range of pH unit values: from 2 to 12

Conductometers, ERA 120.1, EN 27888: 1993, direct comparison method with SRM, the measuring range of conductivity units: from 5 microS to 150 mS

Gas chromatograph with FID, TCD, ECD, FPD, NPD detectors for measuring pesticides and other toxic pollutants OIML R 82, 2006 (E), direct comparison method with SRM, with the concentration measurement range depending on the detector:

- FID: 1pg/s -10 pg/s

- TCD: 300 pg/ml to 10,000 pg/ml

- ECD: 0.1 pg/mL to 10 pg/mL

- FPD: 10 pg/s to 100 pg/s (S), 0.1 pg/s to 5 pg/s (P)

- NPD: 25 pg/s (P), 50 pg/s (N)

Gas chromatographs with a mass detector for analysis of organic pollutants in water, OIML R 83, Edition 2006 (E), direct comparison method with SRM, the atomic mass unit measuring range: 10 amu to 3000 amu.

Refractometers, OIML R 124, direct comparison method with SRM, the refractive index unit measuring range: 1.325 nD to 1.70 nD.

Calibration of areometers is performed by the direct comparison method with areometer standards. Measuring range: 0.6 g/cm3 to 1.3 g/cm3. Direct comparison method PR.17025.21

Calibration of densitometers is performed by the direct comparison method with areometer standards. Measuring range: 0.6 g /cm3 to 1.3 g /cm3. Direct comparison method PR.17025.22

TOC – direct comparison method with SRM. Measuring range: 0.25mg/l to 1000mg/l. Method of measurement TOC-US Environmental Protection Agency NCEA-C-1282 Method of determination of total organic carbon.

Physical testing of air (clean rooms, laminar flow and hazard devices with air filtration, fume hoods) in accordance with SRPS EN ISO 14644, SRPS EN 14175, EN 12469: 2000.

About measuring

In today’s Europe, about 6% of the total gross national product is used on measurements, making metrology a vital part of our daily lives.

In modern times, it is very challenging to describe any phenomenon in everyday life without metrology: sunshine duration, alcohol percentage, daily radiation dose, weight of letters, telephone impulse, room temperature, environmental conditions, tire pressure, room illuminance, strawberry weight on a marketplace, etc.

Systematical measurements with a known uncertainty degree are the basis for industrial quality management. In contemporary industrial production, the costs of unreliable measurements span from 10% to 15% of the total production costs. Moreover, quality and precise measurements have a significant impact on the value, efficiency and quality of manufactured products.

Needless to say, science is based on measurements. Availability of measuring instruments and the possibility to use them efficiently are crucial for providing meaningful research results.

Measurements require collective knowledge. The mutual trust is becoming increasingly important with a growing network of cooperation, introducing harmonized measuring units and methods. Growing activities regarding recognition, accreditation and bilateral or multilateral comparison of calibration, testing etalons (standards) and laboratories in different countries require mutual trust. Thousands of years of history confirm that cooperation in metrology makes life simpler.

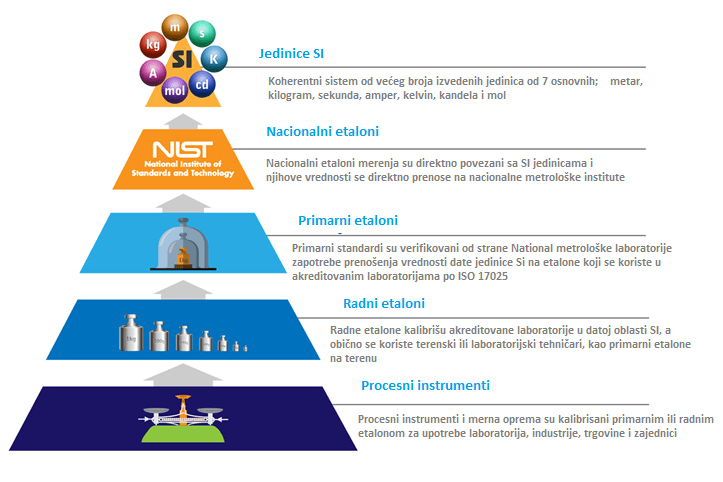

Traceability is a property of measurement results / values of standards, that can be connected with given references, usually national or international standards, through a continuous chain of comparisons, all of which have indicated measurement uncertainties.

The end user can obtain traceability up to the highest international level either directly from the National Metrology Institute or from an accredited laboratory for a given quantity, as shown:

Traceability chain

Measurement uncertainty is a parameter associated with the measurement result, which characterizes the dispersion of values that could otherwise be attributed to the measuring quantity.

The parameter can be, for example, a standard deviation or a half-width interval with a specified confidence level.

Measurement uncertainty includes, in general, several components. Some of them can be estimated based on the statistical distribution of the results obtained in the series of measurements and characterized by experimental standard deviations. Other components, which may also be characterized by standard deviations, are estimated using assumed probability distributions, based on experince or other information.

A standard reference material is a material or substance with one or more of its property values certified by a technically valid procedure. These property values are sufficiently homogeneous and well established so that they can be used to calibrate measuring instruments or systems, in order to evaluate measurement methods or attribute values to materials.

Certified reference materials (CRM) have one or more of their property values certified by a suitable procedure and are accompanied by a certificate. This procedure establishes traceability with the correct realization of the unit in which the property values are expressed and for which each certified value is accompanied by measurement uncertainty at the specified confidence level.

Calibration is a set of procedures which, under certain conditions, establish a relationship between the measured values and the corresponding values achieved by standards. Calibration defines the characteristics of an instrument, measuring system or reference material. This is achieved through a direct comparison of the instrument with a SRM or CRM. A calibration certificate and instrument label are then issued.

Why is it necessary to calibrate your measuring equipment?

There are four main reasons why an instrument needs to be calibrated:

- to establish and prove the traceability of measurements

- to ensure consistency of the values read by the instrument

- to determine the accuracy of the values read by the instrument

- to establish the reliability of the instrument, i.e., to ensure confidence

Customer satisfaction survey

We kindly invite you to complete our survey and help us improve our services. We would like to know whether our offers and/or contracts meet your expectations.

Survey