HERZOG offers the right solution for preparation for all user needs – from full automation to manual stand-alone machines. Various options are available, including machines with a sanding belt or holder / holder for coarse and fine preparation, cooling with sampled water, as well as an optional milling cutter, e.g. for calibration samples. The basic characteristics of HERZOG grinding machines are compact construction, simple operation and the highest safety standards – all with the aim of optimal surface preparation.

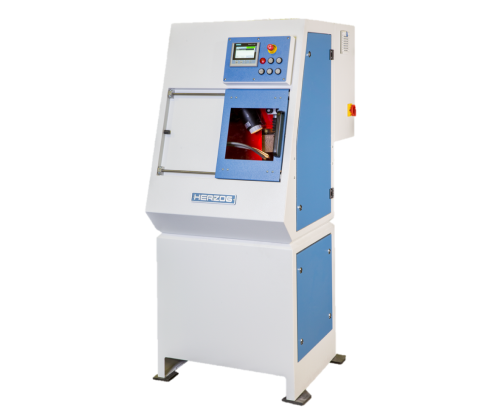

HB 3000, HT 3000, HB 4000 and HBF 4000 – Automatic grinding (and milling) machines

All 4 models are used for coarse and fine grinding of steel and pig iron samples (up to 50 mm in diameter, round or with parallel surfaces) for OES, XRF and other analytical procedures. Operating modes include automatic, stand-alone, linear automation and robot automation.